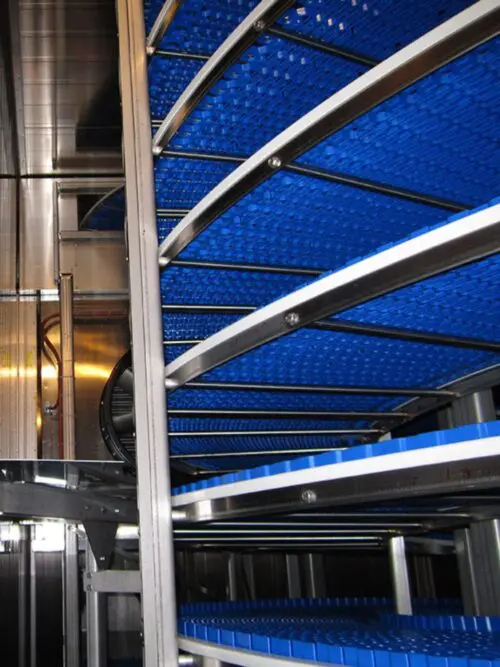

Spiral cooler

Tailor-made spiral cooler conveyor belt for food

Sarp customizable spiral coolers for food processing are composed by conveying belts that move the product and a cooling system that ventilates it. We design and build spiral cooling towers suitable for all the production lines, to optimize the timelines, costs, and production spaces.

Sarp tailor-made solution can ensure excellent performance in terms of:

- Space organization: the spiral system has a circular shape and it is developed in height with a low space between the layers. These characteristics will ensure great performances occupying less space. The shape of the spiral can be customized: round, oval, double spiral, according to your needs.

- Maintenance and cleaning management: every section of the spiral system is easily accessible, to ease washing process. In addition, Sarp design high temperature cleaning systems that require an airtight chamber, resistant to high pressure, thanks to completely welded panels that sealed the room and the floor.

- Handling and storage: we offer you the opportunity to design the transportation paths of the goods and to add storage systems to your production line. These systems are thought to keep the product safe in case the machinery stops, and it allows us to avoid the intervention for restoration, reducing the percentages of waste.

Conveyor belts for the processing of bakery products

Our conveyor belts of Sarp bakery products division are thought to treat packed and bulk pastries. The different functionality can be used in different kinds of products with different processes: drying, leavening, sterilizing, pasteurizing, cooling, freezing, and deep-freezing. The conveyor belts for bread, cakes, pizza, and others bakery products are designed to minimize the waste of space: the spirals are developed in vertical and are dragged by a driving tower, allowing to gain more space in the center of the system, that can be used for treatment devices. Systems for bread freezing allows a high exchange between air and products, near to 100%.

Application areas

Pasteurization, cooling, freezing, drying, proofing of bakery products such as bread, packed or unpacked pastry products.

List of products:

- Bread

- Baton bread

- Pizzas

- Croissants

- Rusks

- Pancake

- Sienese nougat-type delicacy

- Cookies

- Pastry products

- Cakes

- Custard pies

- Desserts

- Ginger Bread

- Pryaniki

- Sushki

Belt conveyors for dairy products

Sarp designs tailor-made systems for the conveying and thermal treatment of packed dairy products. Our machines are ideal for plastic packaging or pre-formed bags. For example, we make systems for cream cheese and for the processing of mozzarella and burrata. Each machine is developed around the needs of your product, to meet the needs of the market, and adapt to the available space and the necessary production times. Our Sarp Lab Research & Development Center monitors and studies the different requests and creates customized processes and machines that follow your requirements.

Application areas

Products used for this application

Belt conveyors for fruit and vegetables

Customized industrial plants for fruit and vegetables treatment Sarp designs customized belt conveyors and thermal treatment systems for fruit and vegetable products based. Our machines are ideal for plastic or paper packages, like bags with cap and spout (doypack, spout pouches, cheer pack, stand up pouches), and also for other types. We realize, for example, fruits and tomatoes purees processing systems. The ideal treatment for these production lines consists of a pasteurizing process or the hot holding process, in order to hold the product at high temperature, that allows to break down the bacterial. The next step is to cool down the package, which allows a fast-thermal shock, necessary for the preservation of the product, and to ensure easy handling or storage of secondary packages. These systems can work by water or by air, according to the functionality of the production line and your needs. We project each machine to answer to the products, pace, and timeline needs, in order to optimize these three aspects. That is why in our Sarp lab research and development center, we are looking for customized solutions, in line with your exigencies.

Application areas

Products used for this application

Belt conveyors for meat

Freezing tunnel for meat Sarp provides its customers with many years of experience in the design and construction of processing systems, in particular in food deep-freezing systems. From stuffed pasta to fish, fruit and vegetables, to confectionery products and meat. We work to customize each production line: let’s start with a consultation on the freezing system for meat that best suits your needs. We process data based on your product, spaces and work organization to offer you the best solution. By choosing Sarp you choose the professionalism of our highly skilled team of engineers, who deal with the design and construction of efficient machines, guaranteeing you to minimize the risks of stopping the production flow. Each machine undergoes some testing tests before being delivered and is covered by a 12 month or 12 + 12 month warranty, which can be extended according to your needs.

Application areas

Products used for this application

Belt conveyors for pet food

For non-food products, Sarp creates conveyor belts designed for the process of packed or unpacked products, dried, sterilized, pasteurized, cooled and frozen products and for the proofing of different types of non-food products. For the process of all non-food products the spiral belt conveyors or towers are suitable to treat any kind of products that need a temperature intervention. Because the machine is essentially a conveying system, any kind of treatment could be applied, from drying to cooling, from freezing to conveying. The spiral belt conveyors or towers could be fit detergents, natural elements as leaves, wood, … and others.

Application areas

Products used for this application

İletişim

Bizimle iletişime geçmek için formu doldurabilirsiniz.

Başarıyla gönderildi.