Shrink wrapping machine Eco Sealer 45

Shrink wrapping machine Eco Sealer 45

The Eco Sealer 45 packaging machine is a low-consumption heat-shrink machine suitable for medium / small production companies such as artisans, commercials, etc. The absolute reliability and high performance, combined with a high operating silence, low energy consumption and ease of use, unique of its kind, make it a cutting-edge product.

Description

Bell-shaped heat-shrink packaging machine easy to use

The shrinking machines, Eco sealer 45 series, are suited to the small/medium companies (artisan and commercial) and the functionality and small dimensions are their main advantages. They are characterized by high performance, reliability, low energy consumption, minimum noise and are very easy to use. All the machine functions are displayed and controlled by the digital control panel. USE: The operator inserts the product into the shrink film, guides it inside the sealing area and close the chamber. Sealing and shrinking are simultaneous.

Features and parameters

Specification

Optional

Features

Specification

Net weight 75 Kg.

Power supply 220 Volt 1Ph

Power supply frequency 50/60 Hz

Installed power 1,6 kW

Dimension sealing bar 440 x 300 mm

Max height product 210 mm.

Max production Up to 300 pph

Max dimension film roll H 450 x ø 250 mm.

Packaging material Pvc, Poliolefin

Film roll thickness Up to 30 my

Optional

- Machine support

- Worktable in stainless steel

Features

- Sealing and shrinking in one operation

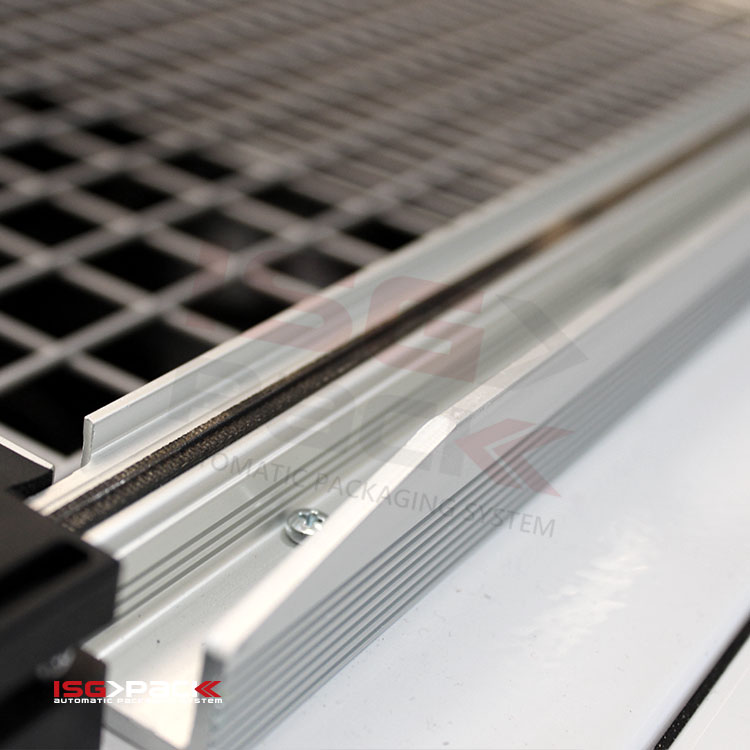

- PTFE-coated sealing blade

- Height adjustment of the internal packaging plate

- Mobile product-holding plate, loose from the film reel support to allow a better adjustment of the film to the pack size

- Hood hold-down electromagnet

- Automatic hood release

- Air cooling of the machine frame

- Alphanumeric LCD control panel equipped with 6 storable work programs and a 16-bit microprocessor card, that allows a simple and precise control of all the machine operations, such as: machine status; number of packs produced by an electronic pack counter; adjustment of the sealing temperature; adjustment of the shrinking time; adjustment of the shrinking chamber temperature; adjustment of the shrinking delay; adjustment of the hood opening delay; troubleshooting

- Long-lasting solid state relays providing easier maintenance

- Reduced power consumption

- Compliance with CE regulation

İletişim

Bizimle iletişime geçmek için formu doldurabilirsiniz.

Başarıyla gönderildi.