Sieve Cleaning Brushes: An Essential Part of the Flour-Sifting Process

Sieve cleaning brushes are critical in the flour-sifting process. Surely, this is also valid for all milling plants regardless of which grain they process. Sieve cleaning brushes are consumables that directly affect product quality, plant capacity and efficiency.

The choice of sieve cleaning brushes plays a significant role in a milling plant’s efficiency, quality consistency, cost control and reliability. Choices made by considering production conditions and requirements enable businesses to obtain many short- and long-term benefits.

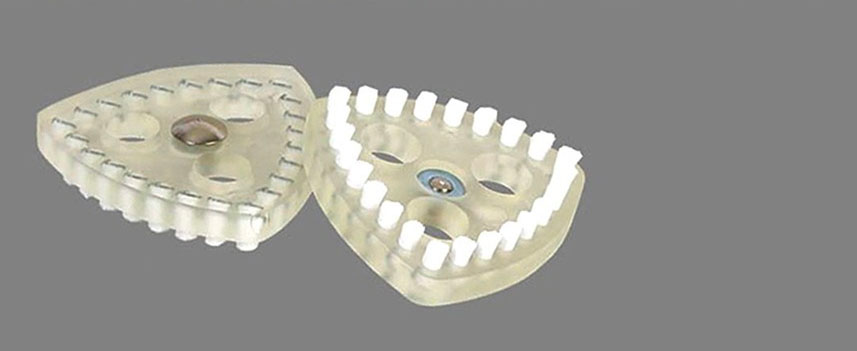

Sieve cleaning brushes are among the important elements of the flour sifting process in mills. Manufactured with various materials in different shapes and sizes, sieve cleaning brushes are one of the critical consumables of grain processing plants. Because the efficiency of sieves depends, among other things, on how intensely and effectively sieve surfaces are cleaned.

Sieve cleaning brushes may vary highly in workmanship, materials, design, size, and weight, although they seem quite simple at first glance. Exposed to intense conditions during operation, these parts come in contact with the sieve frame approximately 350,000 times in a 24-hour continuous working time. Therefore, sieve cleaning brushes must be made of flexible plastic that is of proper hardness for long life.

When a sieve cleaning brush breaks, its parts can damage the sieve surface and contaminate the sieved product. As a result, flour quality is adversely affected, and the mill may need to be stopped, which means an extra burden in terms of both time and costs. Consequently, choosing the right sieve cleaning brush requires particular attention to the material quality and hardness of the plastic.

The same can be said for the sieve cleaning brush’s weight. Brushes that are not heavy enough fail to achieve the dynamic movement to work in harmony with the strong product flow. This, in turn, can cause a decrease in the net sieving area and yield.

It is also important that the material used in the manufacturing of a sieve cleaning brush is heat-resistant. Depending on the ambient conditions of the mill, very high temperatures can occur in sieves and the sieved products. It should be ensured that the working temperature in the machine will not cause the sieve cleaning brush to deform. Because in such cases, brushes cannot perform effective and homogenous cleaning. Sieve cleaning brushes must also be resistant to fats and enzymes to avoid damage and function loss before operating time.

In addition to the material used and the weight, the shape and design of sieve cleaning brushes impact the efficiency of the cleaning operation. This factor should also be considered to ensure optimum sieving area, access to corners, and effective edge cleaning. It is also essential to take into account the impact of the brush material. The quality, material, and workmanship of the brush play a significant role in the effectiveness of cleaning and the durability of the product. The hardness, strength, and material composition of the nylon are the primary determining factors in this respect.

One final point is compatibility with food. In mills, sieve cleaning brushes come in direct contact with food products. As per health requirements, sieve cleaning brushes used in sieve cleaning must be made of food-grade materials.

Since sieve efficiency and effective sieve cleaning are directly associated, it is possible to say that choosing the right sieve cleaning brush is vital in the sieve’s yield, as well as the mill’s net product yield. Thus, it seems reasonable to prioritize high quality when choosing this critical part. This enables many advantages, including prolonged life, high flour quality, and efficiency along with reduced maintenance requirements and additional costs.

If you wish to improve the efficiency and quality of your milling operations, you can contact our sales representatives to learn about our durable, high-quality, and long-lasting pneumatic cylinders and equipment. Regardless of where you are across the world, Regardless of your mill’s location, you can smoothly meet any spare part needs you may have via our e-commerce platform Depart Shop (shop.departspares.com), available 24/7.