Special wrapping machine Box Wrap 800B

Special wrapping machine Box Wrap 800B

The Box Wrap 800 B model is a semi-automatic winder for square or rectangular boxes. Equipped with a 7.2 "color touch screen control panel that allows, in a very simple and functional way, the management of programs and the setting of the wrapping parameters. Machine managed by PLC.

Description

Wrapping machine semi-automatic with stabilizing press for rectangular or square boxes

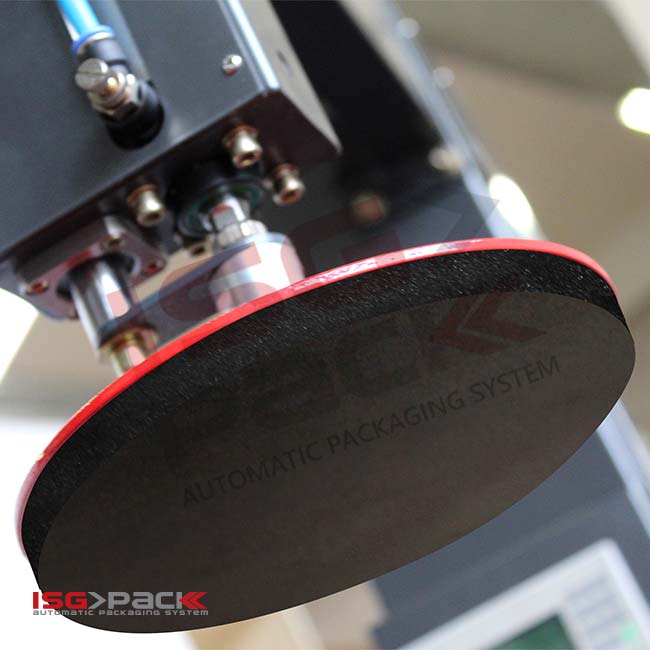

The Box Wrap 800 B is a semi-automatic wrapping machine for square or rectangular boxes. It is equipped with a digital LCD control panel that allows, in a very simple and functional way, the management of programs and the setting of the wrapping parameters, through the digital adjustment of the turns both at the base and at the top of the product, the adjustment table speed, trolley up and down adjustment, photocell reading setting and manual / automatic machine management button. The wrapping machine is electrically powered and requires an installed energy power of 1.25 Kw. As regards the operation of the automatic stabilizer press, it is powered by compressed air with an operating pressure of 6 bar. The reel holder trolley has a fixed ratio motorized pre-stretch system.

“Technical features subject to change without notice”

It has a table diameter of 550 mm with a rotation speed of 20 rpm (rotations per minute). The Box Wrap 800 B winder can process boxes with dimensions of L 250/1000 mm x W 200/1000 mm x H 250/1000 mm, supporting a maximum weight on the plate of 60 Kg. It is possible to adjust the start and gradual stop of the table by inverter.

Features and parameters

Technical details

Specification

Parameters adjustable by control panel

Cycles activated by control panel

Film roll features

Technical details

- Machine structure in painted steel sheet

- Film carriage by transmission chain

- Max product height 1000 mm

- Pneumatic top press

- Machine controlled by PLC and color touch screen 7,2”

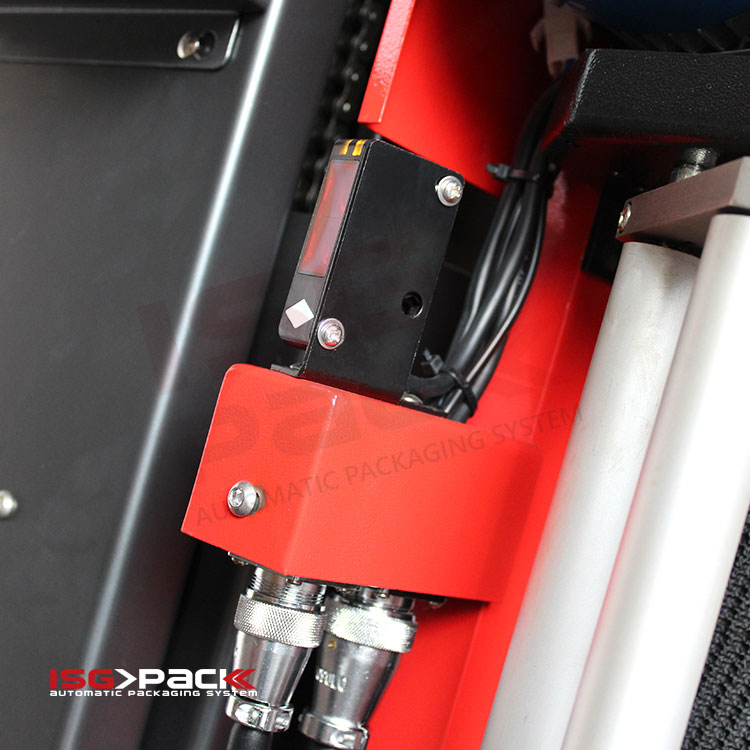

- Safety stop device at the base of the carriage in compliance with the CE regulations

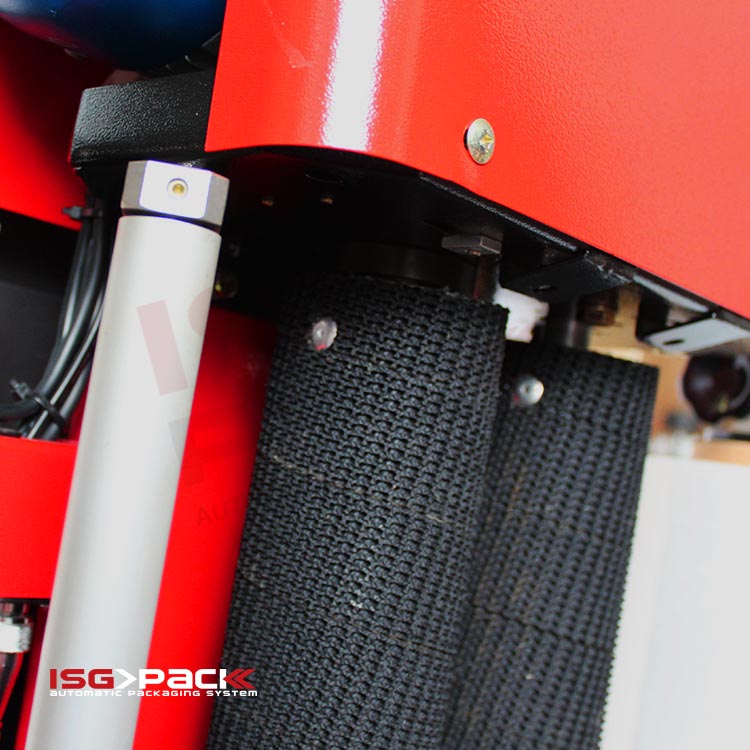

- Motorized pre-stretch set at 200% with possibility to interchange pre-stretch ratio (100%, 150%, 250%)

- Emergency stop in compliance with CE regulations

- Lateral holes for forklifting the machine

- Inverter for soft start and indexed stop of the turntable

- Man / Aut. function

- Cycle counter

Specification

Film pre-stretch Mechanical brake carriage

Machine dimensions L 1500 x W 440 x H 2300 mm

Installed power 1,25 Kw

Turntable speed 0 – 20 rpm

Carriage up-down speed 1,4 – 4 (m/min)

Power supply 220 Volt 1Ph

Power supply frequency 50/60 Hz

Air pressure 6 bar

Weight machine 150 Kg

Max product size L 1000 x W 1000 x H 1000 mm

Dimension Min. product L 250 x W 250 x H 250 mm

Max product weight 60 kg.

Max dimension film roll H 500 mm Ø 250

Film roll max weight 16 Kg

Film roll thickness 12 – 35 (µm)

Photoeye to detect door height std

Forklifting Lateral

Parameters adjustable by control panel

- Adjustment number of rounds at the bottom of the product (start cycle)

- Adjustment number of rounds at the top of the product

- Adjustment number of rounds at the bottom of the product (at the end of the cycle)

- Adjustment turntable speed from 0 to 20 rpm

- Adjustment ascending and descending carriage speed

- Adjustable number of complete cycles

- Overlap adjustment of the film

Cycles activated by control panel

- Cycle ascending and descending

- Cycle only ascending

- Top sheet cycle (ascending / descending)

- N° 8 programmable cycles by touch screen according to the product / pallet to wrap

Film roll features

- Film roll external diameters: 280 mm

- Film roll height: 250 – 500 mm

- Film roll thickness: 12 – 35 my

- Film roll internal diameter: 76 mm

- Film roll max weight: 16 Kg

İletişim

Bizimle iletişime geçmek için formu doldurabilirsiniz.

Başarıyla gönderildi.