Robot wrapping machine Robo Wrapp 600A

Robot wrapping machine Robo Wrapp 600A

Model Robo Wrap 600 is a self-propelled stretch-film wrapping robot for palletized loads with different shapes, sizes and weight. It is equipped with a digital color display 7,2” that allows, in a very simple and functional way, to adjust the programs and the wrapping parameters easily. The start cycle can also be activated by remote control.

Description

Pallet wrapping robot for packing palletized loads of any shape, weight and size.

Model Robo Wrap 600 A is a self-propelled stretch-film wrapping robot for palletized loads with different shapes, sizes and weight. It is equipped with a digital color display 7,2” that allows, in a very simple and functional way, to regulate the programs and the wrapping parameters easily.

Controls and security

The movement of the pallet wrapping robot takes place electrically thanks to the 2 controls located on the steering wheel. The self-propelled robot is fitted at the front with a safety bumper that allows the machine to be immediately stopped should it hit an operator or an obstacle.

As an alternative to this self-propelled wrapping robot, the Robo Wrap 600 B pallet wrapping robot is also equipped with motorized pre-stretch with fixed ratios.

General characteristics of the pallet wrapping robotrobot avvolgipallet

The Robo Wrap 600 A pallet wrapping robot can wrap products with a minimum size of L 600 x W 600 x H 2300 mm and with unlimited weight. The machine is equipped with a Siemens PLC and a 7,2 color touch screen display that allow you to adjust further parameters such as the carriage ascent and descent speed, photocell reading delay, cycle counter, etc.

Features and parameters

Technical details

Specification

Parameters adjustable by control panel

Cycles activated by control panel

Film roll features

Technical details

- Film carriage by transmission chain

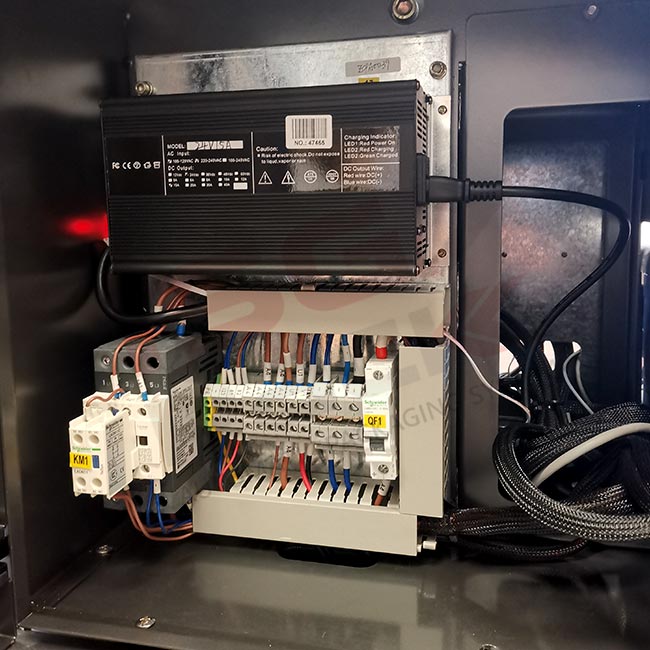

- 2 AGV battery 12 volt – 120 Ah serial connected

- High frequency battery charger integrated

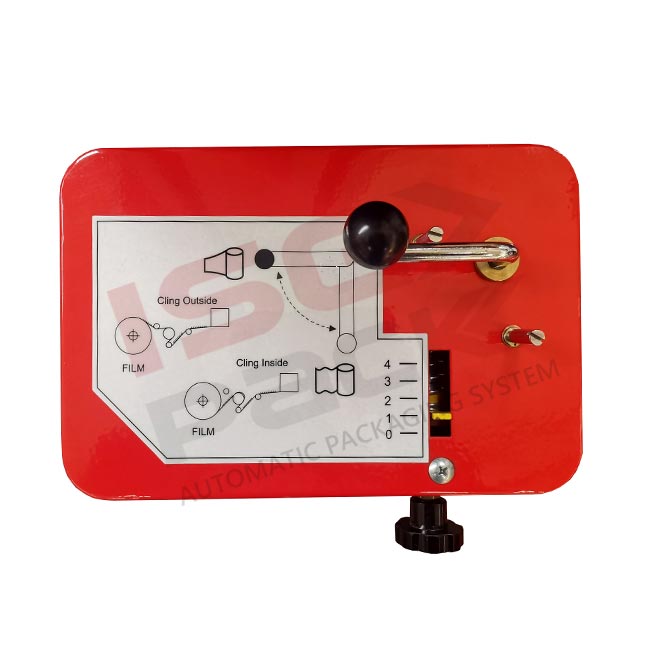

- Film tensioning by mechanical brake

- Emegency stop in compliance with CE regulations

- Safety bumper

- Full charge cycle time of 8 hours

- Lateral contact wheel with adjustable height

- Control panel with color 7,2” touch screen

- Machine controlled by PLC SIEMENS S7/200

- Acoustic wearning and lamp at the cycle start

- Up to 150 pallets (L1200 x W 800 x 1500 mm)

- Emergency wheel in case of low battery

- Handle release system for moving the robot

- Cycle counter

- Manual working mode

Specification

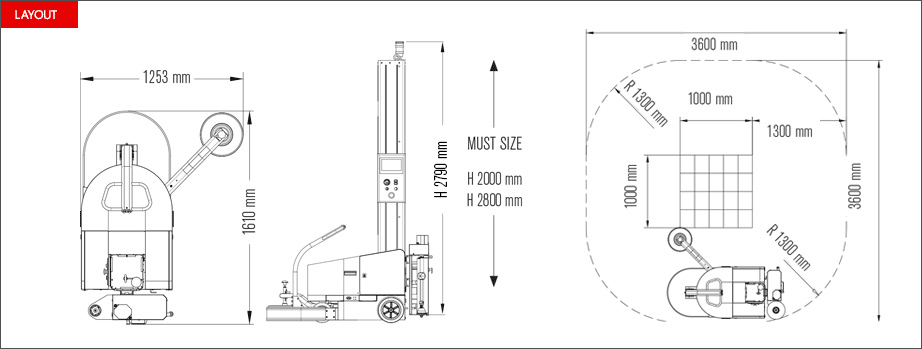

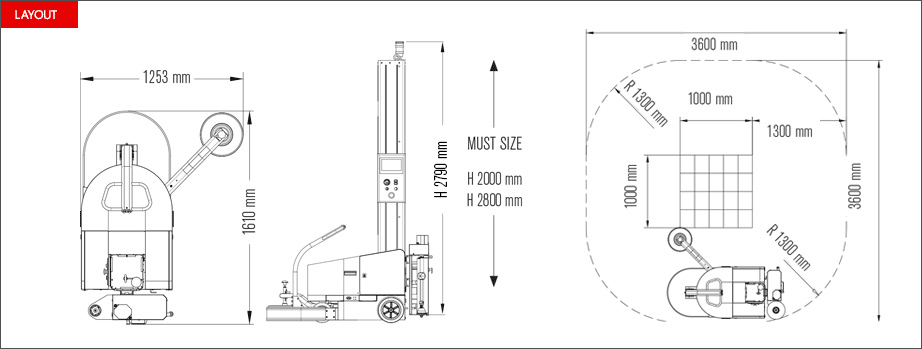

Machine dimensions L 1610 x W 1253 x H 2790

Weight machine 450 Kg

Max product weight No limit

Carriage up-down speed 1,4/5 metri/min

Film tensioning Mechanical brake

Power supply 220 Volt 1Ph

Power supply frequency 50/60 Hz

Installed power 1 Kw

Max dimension film roll H 500 mm Ø 280 mm

Coil outer diameter 280 mm

Reel internal diameter 76 mm

Film roll max weight 16 Kg

Film roll thickness 12 – 35 (µm)

Photoeye to detect door height std

Forklifting Lateral

Parameters adjustable by control panel

- Number of rounds at the bottom of the pallet

- Number of rounds at the top of the pallet

- Adjustable rotating speed from 35 – 90 mt/min

- Adjustable ascending carriage speed

- Adjustable descending carriage speed

- Adjustable number of ascending and descending cycles

- Adjustable photocell delay

Cycles activated by control panel

- Ascending and descending cycle

- Only ascending cycle

- Reinforce cycle at a programmed height (ascending cycle, ascending/descending cycle)

- Altimeter cycle (pallet height setting) to detect the pallet excluding the photocell

- Top sheet cycle (ascending/descending)

- N° 10 programmable cycles by touch screen according to the product/pallet to wrap

Film roll features

- Film roll external diameters: 280 mm

- Film roll height: 500 mm

- Film roll thickness: 12 – 35 my

- Film roll internal diameter: 76 mm

- Film roll max weight: 16 Kg

İletişim

Bizimle iletişime geçmek için formu doldurabilirsiniz.

Başarıyla gönderildi.